Monolithic Insulating Joints

What are the Monolithic Insulating Joints?

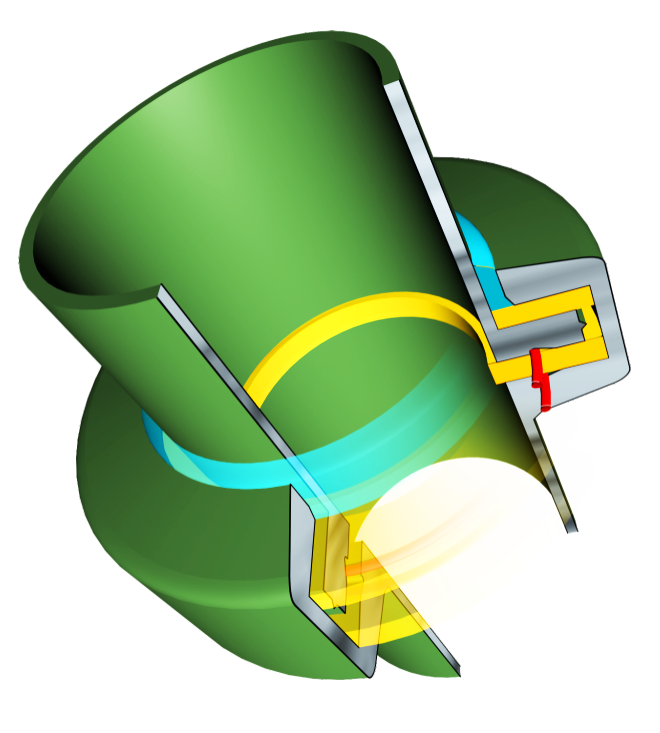

Monolithic Insulating Joint is a metal-insulated, non-seamable, prefabricated construction

with or without a spark gap to ensure electrical discontinuity of the pipeline in which it is installed.

Use of a Monolithic Insulating Joint

- Underground and aboveground transmission and distribution pipelines,

- Existing and under construction facilities,

- In front and behind gas reduction stations,

- Aboveground and underground gas and crude oil storage facilities,

- Tanks and installations for liquid and gaseous fuels.

Mechanical properties

- Monolithic Insulating Joints bodies are made as welded structures from thick metal sheets (carbon or low alloy structural steel),

- Results of measurements and tests are included in documentation enclosed with our products.

Electrical properties

- The quality is guaranteed by the use of high-class insulating materials,

- The use of exchangeable spark gaps,

- No sparking or breakdown during the electrical test with alternating voltage of 5 kV (50 Hz) for 1 min. (test performed before and after hydrostatic test),

- Resistance of Monolithic Insulating Joints above 1GΩ at 1kV in the dry state,

- No breakdown at a voltage of 15 ÷ 25 kV (depending on requirements) when checking external insulation coating with holiday testing.

Calculations

- Standard according to WUDT-UC-WO-0, PN-EN 13480-3 and ASME VIII Div. 1

Additional values such as bending moment and bursting forces can be imposed by customer,

- Necessary parameter for calculation is the working pressure.

Materials

Pipe use for welding according to

PN-EN ISO 3183, PN-EN 10028, DIN 1626, API Spec 5L, ASTM A53 and other,

- Steel elements (rings) made of sheet metal, metallurgical rings and forgings according to PN-EN 10028,

- Insilating materials are laminated epoxy boards according to PN-EN 60893 and DIN 7735

Welding and non-destructive testing

- The steel elements of the Monolithic Insulating Joints are joined together by MAG welding in accordance with approved procedures by an independent certification body,

- The welds are examined using non-destructive methods: VT (visual testing), PT (penetrant testing) and UT (ultrasonic testing) by 2nd level specialists holding competence certificates issued by the Welding Institute.

Applied exterior coatings

- Polyurethane coatings according to EN 10290,

- Heat–shrinkable coatings acc. to PN-EN 12068, “CANUSA” “REIHEM”.

- Paint coatings (epoxy) acc. to PN-EN 12944.

Internal coatings used

- Paint coatings (epoxy) acc. to PN-EN 12944, PN-EN 10301.

Testing

- Construction, dimensions, materials,

- Hydrostatic strength test with pressure 1.5xMOP (maximum working pressure),

- Pneumatic tightness test at a pressure of 6 bar,

- Electrical test with 5kV/50Hz alternating voltage for 1 minute (no sparking),

- Resistance above 1GΩ at 1 kV DC.

Scope of performance

- It is possible to supply Monolithic Insulating Joints with increased working parameters, i.e. working pressure up to 420 bar (ANSI 2500), working temperature -50°C ÷ 180°C,

- additionally with internal, external spark gap or with adjustment for external spark gap.

Product gallery

We provide solutions for the gas and oil industry

If you have any questions – please contact us