Linear Expansion Joints

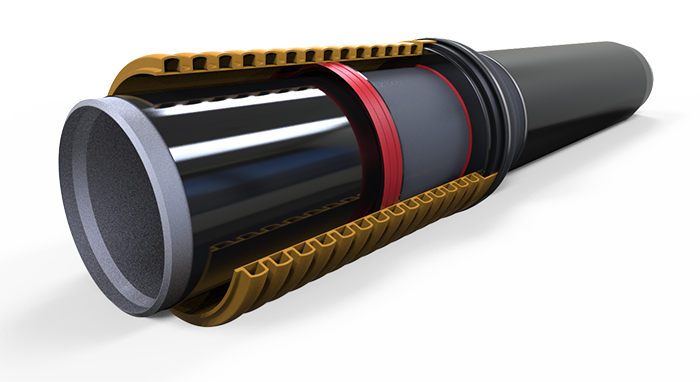

Linear Expansion Joints type KLR

Linear Expansion Joints manufactured by RADIATYM are intended for large linear compensation of pipelines (they take over increase or decrease of pipelines‘ linear dimensions). Compensators in standard design are intended for work in conditions specified by the Manufacturer. It is possible to manufacture compensators to work in other conditions (pressure, temperature, compensator capacity), may be made of other materials, according to the user’s needs as well as with external covers and other terminations for conduits. Each compensator may be equipped with a possibility of compensation monitoring. For this purpose the patented “EXTENT” system is used.

Use

Linear compensators find their use:

- in areas where landslides are expected due to underground mining,

- in areas with high seismic activity,

- on sloping (mountainous) terrains where landslides may occur,

- on building structures where large pipeline compensation is inticipated.

Main advantages of Linear Expansion Joints

- They do not require supervision and periodical maintenance.

- They are adapted to work on pipelines included in the system of active cathodic protection of high insulation tightness (not less than 1 x 10 Ωm).

- Protected against complete separation.

- The applied system of longitudinal compensation measurement (“EXTENT”) enables simultaneous measurement of insertion/extension with limited angular adjustment of the inner pipe against the compensator’s body by max. +/- 5°.

- The linear extension joint structure is equipped with a flange enabling correction of the central position on the pipeline (using an external force system owned by the Manufacturer).

The design is adapted for bilateral pipeline pigging (optionally).

The linear extension joint is equipped with an oil chamber, which enables smooth operation after a longer period of inactivity.

Mechanical properties

Tests, trials and many years of experience confirm the correctness of the applied construction solution and production technology.

Electrical properties

Strength calculations

Standard, according to WUDT/UC/2003 and EN 1594; additional parameters such as external bending moment may be imposed by the customer. Important data for the calculation is Customer’s determination of the maximum operating pressure (MOP), external loads and material assumptions.

Materials

Steel parts are made of high-grade pipes and sheets; all seals are resistant to ageing and selected for flowing through the pipelines medium with regards to chemical, temperature and pressure resistance. The materials are also selected in agreement with the Customer.

Use

For transmission and distribution pipelines for gas, water and liquid fuels. For use in overground and underground pipelines.

External coating

Internal coatings

Standard, Epoxy coating according to PN-EN 10301, there is a possibility of coating to the requirements of the Customer.

Standard dimensions

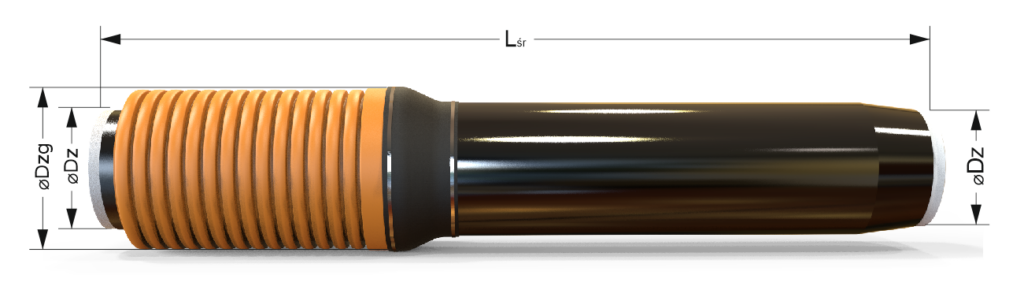

| DN | Dz [mm] | Dzg [mm] | Lśr [mm] | Compensation range |

|---|---|---|---|---|

| 100 | 114,3 | 250,0 | 3800 | 800 |

| 150 | 168,3 | 300,0 | 3800 | 800 |

| 200 | 219,1 | 350,0 | 4000 | 800 |

| 250 | 273,0 | 400,0 | 4000 | 800 |

| 300 | 323,9 | 494,0 | 4200 | 800 |

| 350 | 355,6 | 525,0 | 4200 | 800 |

| 400 | 406,4 | 600,0 | 4400 | 800 |

| 450 | 457,0 | 660,0 | 4400 | 800 |

| 500 | 508,0 | 720,0 | 4400 | 800 |

| 600 | 610,0 | 785,0 | 4400 | 800 |

| 700 | 711,0 | 890,0 | 5000 | 800 |

| 800 | 813,0 | 1000,0 | 5000 | 800 |

| 900 | 914,0 | 1100,0 | 5240 | 800 |

| 1000 | 1016,0 | 1256,0 | 5240 | 800 |

* Lśr – Linear Extension Jont length in the middle position of the compensation range

For standard version includes:

- max. working pressure MOP100 (10 [MPa]),

- working temperature range from -30[°C] to +50[°C],

- compensation range ±400 [mm] (can be made according to the Customer’s requirements).

Other parameters upon request.

Inspection and acceptance

As a standard, each compensator is tested in accordance with WUDT/UC/2003, PN-EN 1594 and our own procedures.

Completion types of KLR

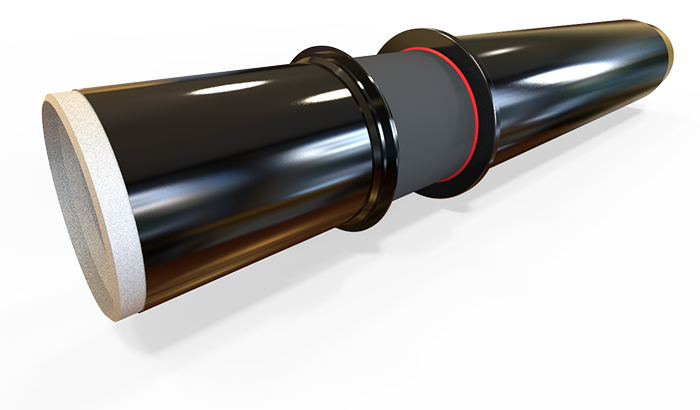

Above-ground installation

Compensator is designed for above-ground installation – piston rod protected with folding sheath.

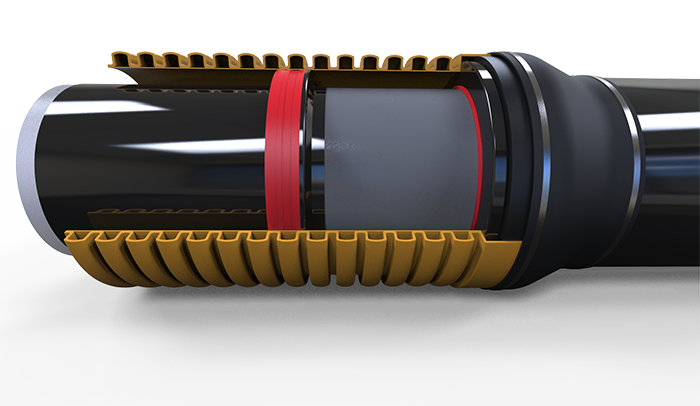

Underground installation

Compensator designed for underground installation – piston rod protected with corrugated sheath pipe of increased mechanical resistance and additional sealing to protect against moisture and dirt.

Product gallery

Product gallery

We provide solutions for the gas and oil industry

If you have any questions – please contact us