Isolating Flange Connections - IPK

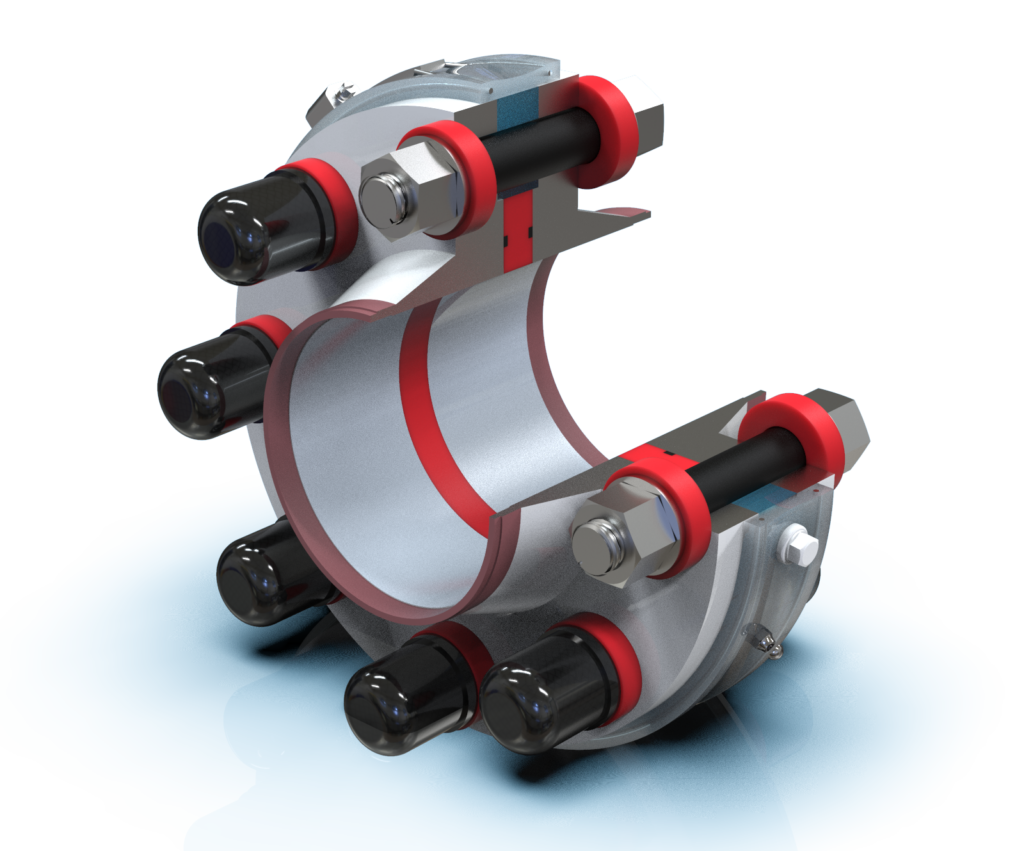

Isolating Flange Connection (IPK)

The Isolating Flange Connection (IPK) is an assembly of two flanges forcibly connected to each other, between which an insulating insert is mounted to break the electrical continuity of the pipeline in which it is installed. In our offer you will also find Insulating Flange Connections with AntiWET type corrosion protection band.

Use

- Existing and during construction facilities.

- Transmission and distribution pipelines for gas, liquid fuels and water,

- In front and behind gas reduction stations,

- Gas and oil mine storage facilities,

- Tanks and installations for liquid and gaseous fuels,

- Underground and aboveground installation.

Mechanical properties

- High mechanical strength achieved through a threaded connection (assembly pressure of flanges).

- Tightness is guaranteed by the use of high quality sealing materials,

- Measurement and testing results are included in documentation enclosed with our products.

Electrical properties

- The use of high-class insulating materials is a guarantee of quality.

- No sparking or breakdown during the electrical test with 5 kV (50 Hz) alternating voltage for 1 min. (test performed before and after hydrostatic test)

- resistance above 10MΩ at standard voltage of 1 kV in dry state (on special request even above 1GΩ).

Tests

- Construction, dimensions, materials,

- Hydrostatic pressure test 1.5xMOP/30min (only when IPK is supplied with flanges),

- Pneumatic leakage test at 6 bar/10min (only when IPK is supplied with flanges),

- electrical test with AC voltage of 5kV / 50 Hz for 1 minute (no sparking),

- measurement of cross resistance at DC voltage of 1kV.

Scope of Performance

- Standard IPK is produced for pressures PN10, PN16, PN25, PN40, PN63, PN100,

- Diameter range from DN10 to DN1200,

- Standard production for working temperature -30C to 80C,

- It is possible to supply IPK with pipe sections welded on both sides,

- We deliver IPK with external sparks at request

- We take into consideration all standards for flanges

- IPK dimensions depend on dimensions of used flanges

- Optionally with protection against moisture penetration.

Calculations

- Standard, according to WUDT-UC-WO-O and PN-EN 13480-3,

- Necessary parameter for calculation is the maximum working pressure MOP,

Materials

- Steel flanges acc. to PN-EN 1092-1, PN-ISO 7005-1, ASME B16.5 and others,

- Steel bolts and nuts acc. to PN-EN 1515-1, PN-EN 1515-2 and others,

- Sealing type “O” of nitrile, fluoride or silicone rubber resistant to ageing and all commonly used media,

- Insulating material is laminated epoxy board according to PN-EN 60893 and DIN 7735

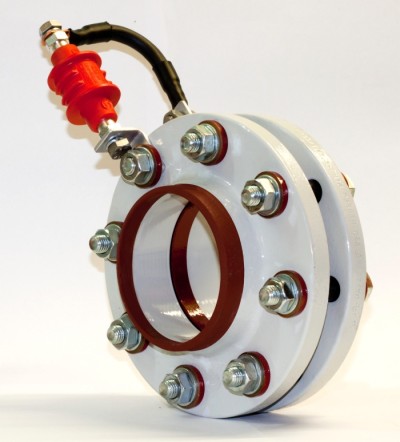

IPK with separating spark gap for equalizing voltage potential

Separating spark gaps with low jump voltage are used to equalize voltage potentials according to EN 62305. It has ATEX certificate. We also offer spark gaps with a waterproof material covering along the entire length of the spark gap, which makes it possible to install the spark gap in underground installations.

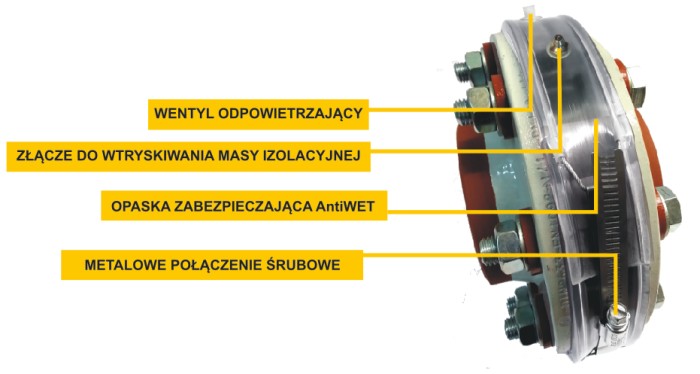

AntiWET safety band

The AntiWET protection bands are used to protect the steel flange rings, gasket and insulating spacer in IPK connections against water penetration. Control and awareness of the damage caused by corrosion is fundamental for pipeline maintenance. By use of a flange band and a corrosion inhibiting agent in the form of a gel insulating mass, the flanges remain protected for many years preventing breakdowns and downtime in the pipeline. Used vent allows even distribution of the synthetic gel mass over the entire space between two flanges.

Product gallery

We provide solutions for the gas and oil industry

If you have any questions – please contact us